The choice of mining method is largely determined by the geology of the coal deposit. Underground mining currently accounts for about 60% of world coal production, although in several important coal producing countries surface mining is more common. Surface mining accounts for around 80% of production in Australia, while in the USA it is used for about 67% of production.

Underground Mining

There are two main methods of underground mining: room-and-pillar and longwall mining. In room-and-pillar mining, coal deposits are mined by cutting a network of ‘rooms’ into the coal seam and leaving behind ‘pillars’ of coal to support the roof of the mine. These pillars can be up to 40% of the total coal in the seam – although this coal can sometimes be recovered at a later stage. This can be achieved in what is known as ‘retreat mining’, where coal is mined from the pillars as workers retreat. The roof is then allowed to collapse and the mine is abandoned.

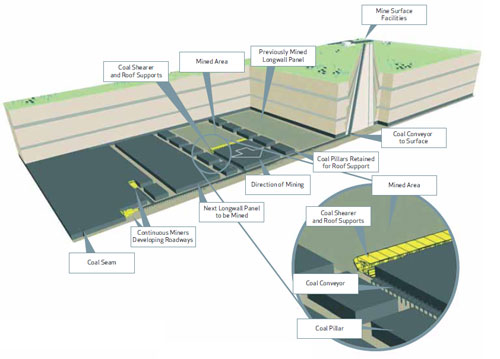

Longwall mining involves the full extraction of coal from a section of the seam or ‘face’ using mechanical shearers. A longwall face requires careful planning to ensure favourable geology exists throughout the section before development work begins. The coal ‘face’ can vary in length from 100-350m. Selfadvancing, hydraulically-powered supports temporarily hold up the roof while coal is extracted. When coal has been extracted from the area, the roof is allowed to collapse. Over 75% of the coal in the deposit can be extracted from panels of coal that can extend 3km through the coal seam.

The main advantage of room–and-pillar mining over longwall mining is that it allows coal production to start much more quickly, using mobile machinery that costs under $5 million (longwall mining machinery can cost $50 million).

The choice of mining technique is site specific but always based on economic considerations; differences even within a single mine can lead to both methods being used.

Surface Mining

Surface mining – also known as opencast or opencut mining – is only economic when the coal seam is near the surface. This method recovers a higher proportion of the coal deposit than underground mining as all coal seams are exploited – 90% or more of the coal can be recovered. Large opencast mines can cover an area of many square kilometres and use very large pieces of equipment, including: draglines, which remove the overburden; power shovels; large trucks, which transport overburden and coal; bucket wheel excavators; and conveyors.

The overburden of soil and rock is first broken up by explosives; it is then removed by draglines or by shovel and truck. Once the coal seam is exposed, it is drilled, fractured and systematically mined in strips. The coal is then loaded on to large trucks or conveyors for transport to either the coal preparation plant or direct to where it will be used.

Coal Preparation

Coal straight from the ground, known as runof- mine (ROM) coal, often contains unwanted impurities such as rock and dirt and comes in a mixture of different-sized fragments.

However, coal users need coal of a consistent quality. Coal preparation – also known as coal beneficiation or coal washing – refers to the treatment of ROM coal to ensure a consistent quality and to enhance its suitability for particular end-uses.

The treatment depends on the properties of the coal and its intended use. It may require only simple crushing or it may need to go through a complex treatment process to reduce impurities.

To remove impurities, the raw run-of-mine coal is crushed and then separated into various size fractions. Larger material is usually treated using ‘dense medium separation’. In this process, the coal is separated from other impurities by being floated in a tank containing a liquid of specific gravity, usually a suspension of finely ground magnetite. As the coal is lighter, it floats and can be separated off, while heavier rock and other impurities sink and are removed as waste.

The smaller size fractions are treated in a number of ways, usually based on differences in mass, such as in centrifuges. A centrifuge is a machine which turns a container around very quickly, causing solids and liquids inside it to separate. Alternative methods use the different surface properties of coal and waste. In ‘froth flotation’, coal particles are removed in a froth produced by blowing air into a water bath containing chemical reagents. The bubbles attract the coal but not the waste and are skimmed off to recover the coal fines. Recent technological developments have helped increase the recovery of ultra fine coal material.

Coal Transportation

The way that coal is transported to where it will be used depends on the distance to be covered. Coal is generally transported by conveyor or truck over short distances. Trains and barges are used for longer distances within domestic markets, or alternatively coal can be mixed with water to form a coal slurry and transported through a pipeline.

Ships are commonly used for international transportation, in sizes ranging from Handymax (40-60,000 DWT), Panamax (about 60-80,000 DWT) to large Capesize vessels (about 80,000+ DWT). Around 700 million tonnes (Mt) of coal was traded internationally in 2003 and around 90% of this was seaborne trade. Coal transportation can be very expensive – in some instances it accounts for up to 70% of the delivered cost of coal. Measures are taken at every stage of coal transportation and storage to minimise environmental impacts (see Section 5 for more information on coal and the environment).

Safety at Coal Mines

The coal industry takes the issue of safety very seriously. Coal mining deep underground involves a higher safety risk than coal mined in opencast pits. However, modern coal mines have rigorous safety procedures, health and safety standards and worker education and training, which have led to significant improvements in safety levels in both underground and opencast mining (see graph on page 11 for a comparison of safety levels in US coal mining compared to other industry sectors).

There are still problems within the industry. The majority of coal mine accidents and fatalities occur in China. Most accidents are in small scale town and village mines, often illegally operated, where mining techniques are labour intensive and use very basic equipment. The Chinese government is taking steps to improve safety levels, including the forced closure of small-scale mines and those that fail to meet safety standards.

Coal Mining & the Wider Community

Coal mining generally takes place in rural areas where mining and the associated industries are usually one of, if not, the largest employers in the area. It is estimated that coal employs over 7 million people worldwide, 90% of whom are in developing countries.

Not only does coal mining directly employ millions worldwide, it generates income and employment in other regional industries that are dependent on coal mining. These industries provide goods and services into coal mining, such as fuel, electricity, and equipment, or are dependent on expenditure from employees of coal mines.

Large-scale coal mines provide a significant source of local income in the form of wages, community programmes and inputs into production in the local economy. However, mining and energy extraction can sometimes lead to land use conflicts and difficulties in relationships with neighbours and local communities. Many conflicts over land use can be resolved by highlighting that mining is only a temporary land use. Mine rehabilitation means that the land can be used once again for other purposes after mine closure.