The Gulin InLine Pressure Jig is a unique and efficient gravity separation device, which has found a wide variety of applications within the mining industry. The unit was originally developed in Australia for recovery of placer gold. The IPJ very quickly moved into the recovery of gold in grinding circuits given the unit’s low water consumption and capital cost benefits. In the late 1990’s research into the use of the IPJ in diamonds was commenced envisaging a number of potential benefits including security, low cost performance and simplicity of operation. Some of the advantages and applications of the IPJ in the recovery of diamonds including actual operating plant experience are covered in this paper. Other potential applications and the use of the IPJ for environmental rehabilitation are also discussed.

Introduction

The InLine Pressure Jig (IPJ) is an effective and efficient gravity separation device that has found application in the processing of a wide variety of minerals. While based on the same principles as traditional jigs, its pressurised design and advanced control system give it many advantages including high recovery, high unit throughput, low water use, close control of operating conditions, low installation cost, low operating costs and high security. The IPJ can be used either in placer deposits as the primary concentrator or in hard rock circuits to treat all or part of the cyclone underflow or mill discharge. As a result of the large range of jig parameters and ragging types possible, the IPJ has successfully been used for a range of minerals, including gold, sulphides, silver, native copper, tantalum, garnet and diamonds.

The IPJ is a compact, low cost continuous process that requires minimal infrastructure or logistical support. In addition to its low capital cost, it has very low operating costs per volume treated, and very low power requirements. Hutch water can be supplied from the ocean, rivers, boreholes, thickener overflow or slimes dam return. Trials using de-sliming cyclone overflow as hutch water have been conducted without any noticeable adverse effect on jig performance up to 5-6% solids w/w. The IPJ requires as little as 10% of the water consumption of traditional jigs.

There are currently over 100 IPJ’s in operation around the World, many in Africa treating a variety of minerals, including 13 currently used in diamond applications.

Theory of Operation

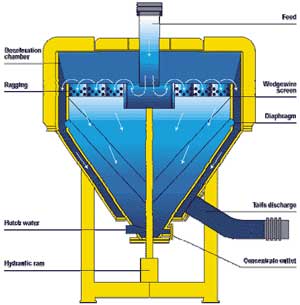

The IPJ is unique in its design and use of jigging concepts. The unit is fully encapsulated and pressurised, and combines a circular bed with a moveable sieve action. The encapsulation allows the IPJ to be completely filled with slurry and water. As a result, slurry velocity is slowed and water surface tension eliminated improving recovery potential. The screen is pulsed vertically by a hydraulically driven shaft. Length of stroke and speed of up and down stroke can be varied to suit the application. Screen aperture, ragging dimension and ragging material can also be altered for the application. An overview is shown in Figure 1 below.

Separation of values from gangue particles occurs based on relative density as well as particle size and shape. High specific gravity particles are drawn into the concentrate hutch during the suction stroke of the bed and are continuously discharged. The lighter gangue is discharged over the tailboard to the outer cone. Both concentrates and tailings are discharged under pressure.

Advantages

- Low water consumption: The IPJ’s low impact on water balance allows grinding circuit operators to treat the full recirculating load and maximise the gravity recovery of minerals, gems or waste materials. In arid areas the availability of water can severely limit the use of gravity treatment options.

- High yield, high recovery: As a continuous concentrate discharge unit, the IPJ offers a high degree of flexibility. Mass pull to concentrate can be varied from 0.5% up to 30% to optimise performance for a particular application.

- Minimise grinding requirements: By recovering minerals or gems at their coarsest fraction the potential to recover by gravity is improved and over grinding of minerals is minimised.

- Wide feed and particle size recovery: Feed sizing of up to 30mm is acceptable. In many circumstances this may eliminate the requirement for an additional screening step.

- Easy retrofit: Given the pressurised nature of the IPJ, the unit can be easily retrofitted at ground level if desired. Tailings will return to mill discharge without the need for additional pumping.

- Cost savings: The design of the IPJ is very efficient for the volume treated. As a result, capital and operating cost savings can be significant.

Gold Recovery by Gravity and the South African Mining sector

The introduction of gravity concentration systems into South African mineral processing plants has tended to lag behind the trend in the world’s other major gold producing nations. This factor reflects both the engineering complexity issues in South African circuits as well as a concern over the security issues associated with the concentration of coarse free gold.

Areas in which the engineering characteristics of the South African industry vary from their foreign counterparts include the incidence of multiple smaller mills with associated screening, significantly higher levels of foreign material including steel and , single large diameter cyclones and high scat levels. As a general rule the South African gold mines run cyclones at low solids densities which diminishes the likelihood of coarse gold particles reporting to cyclone overflow.

A number of factors have encouraged the local industry to move towards the installation of gravity circuits including the success of similar circuits worldwide and the introduction of intensive leach technology (which both enhances gravity circuit performance and eliminates security issues associated with hands on tabling processes).

Given the unique design issues for the local plants it has become evident that the design and engineering of the gravity circuit is of utmost importance to achieve full potential for these installations. As a result, Gulin has developed, through collaboration and onsite trials, a comprehensive optimisation package. An outline of a number of recommended engineering solutions are discussed later in this paper.