What is the Density of crushed stone?

For solid rock is usually 2.7T/m3 (+/- 10%), and generally not crushed stone.

Crushed stone of uniform size has a nominal density of 100 pounds per cubic foot (1.6 Metric Tons per cubic Meter).

If the crushed stone is a mixture of various sizes, then the open spaces that would be present in crushed stone of uniform size will be filled somewhat by the smaller sizes, and density increases. Typical effective density here ranges from 120 – 140 pounds per cubic foot (1.9 – 2.2 Metric Tons per cubic Meter).

Solid Rock will be close to 150 – 170 pounds per cubic foot (2.4 – 2.7 Metric Tons per cubic Meter).

Crushed stone density is variable depending on the type of stone, the stone crushing machinery, and how the crushed stone is sorted after crushing.

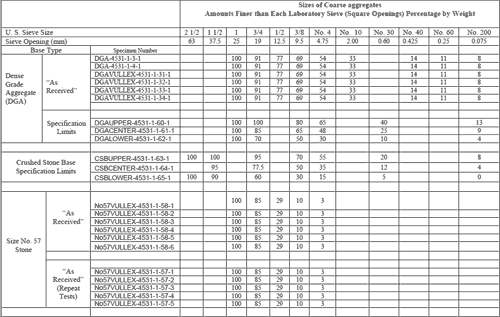

Aggregate size

The size of an aggregate is not quite what it seems.

The size of a particular aggregate will depend on what sieve sizes determine the grading of an individual material, or in the case of a quarry what screen sizes are used to separate out crushed aggregate.

If you have a material where the normal sieve/screen sizes are, 37.5mm., 28mm., 14mm., 10mm., 6.3mm. etc.,

A 28mm. aggregate will be that aggregate which passes the 28mm. sieve and is retained on the 20mm. sieve.

So, in the case of a 28mm. aggregate the size could be 27.9mm or 20.1mm., and still be regarded as a “28mm. aggregate”.

This variance in true size can be a particular problem with surface dressing chippings, which are single size.

It leads to such expressions as a “bold” 10mm. chipping, or a “small” 10mm. chipping, meaning the bulk of the chippings are quite near the 10 mm. sizes or the 6.3mm. size.

Chippings being “bold” or “small” can necessitate a change in binder spread rates to ensure retention of the chipping, or to prevent “fatting up” of binder.