Magnetite Resources

Magnetite Dressing Plant

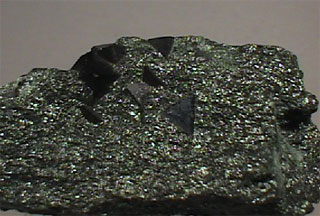

Magnetite is a ferrimagnetic mineral. Magnetite is black or brownish-black with a metallic luster and belongs to iron oxides and spinel group.

Magnetite is sometimes found in large quantities in beach sand. Large deposits of magnetite are found in Chile, Uruguay, Sweden, Australia, America, Norway, Germany, Italy, Switzerland, South Africa, India, Mexico and Peru.

Magnetite Ore Crusher

Magnetite has a Mohs hardness of 5–6 and a black streak.

Due to the high hardness, jaw crusher, cone crusher and mobile crusher are usually used as magnetite ore crusher and ball mill, MTW grinding mill, MTW grinding mill and LM series grinding machine are used as magnetite grinding machines. Jaw crushers, cone crushers and some other equipment are used in magnetite crushing plant, through the final products size is able to meet sand size. Ball mills are usually used in magnetite ore grinding plant and magnetite processing plants. Also, some other magnetite ore concentrating equipments like spiral classifier, rod mill, magnetic separator are widely used in magnetite beneficiation plants.

Magnetite Ore Beneficiation Plant Flow

When blast or digger out from the underground or from the mountain, the excavator carry the raw magnetite to the magnetite crushing site and dump the raw magnetite lump to the hopper. Then the vibrating feeder under the hopper feed the raw material to the magnetite crushers steady. The jaw crusher used in primary crushing process will crush it to small lumps until it meet the feed size of the cone crusher used in the secondary crushing process. Through the crushing process, the vibrating screen separates them from the mixture according to the size range. Finally, they are transported to the store pile sits.

In magnetite beneficiation process, the crushed magnetite ore (it is about 0~12mm) are fed to ball mill for magnetite grinding. When the magnetite particles are ground to 0.2~0.3mm. To big scale and medium scale magnetite producers, one stage grinding and magnetic separating process. Ground and discharged from the ball mill, the spiral classifier clean and separate the particles and qualified particles are conveyed to dehydration tank. Then the magnetic separator will select the valuable and finally gangue will magnetic.

To some magnetite producers, they may adopt Multi-Stage magnetic dressing process; it is quite similar with the former. Also the reverse flotation and low-intensity magnetic separation are adopted in magnetite ore beneficiation production line. Designs depend on the customer requirement and the raw mineral character.

If you want to know more details or if you have some doubts, just be free to contact us. You can get the price and specification immediately by chatting with our engineer on-line. Also, you can leave your requirements; we will answer you by email in within 24 hours.