High Performance for Higher Profitability

CS Cone Crusher

CS (High Performance) Series cone crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and ior product quality, and in providing a wider range of application suitability. From lime- stone to taconite, from ballast production to manufactured sand, and from small portable plants, CS cone crushers provide unbeatable performance in secondary, tertiary, and quaternary applications.

Higher capacity

Thanks to the patented combination of higher speed and throw, which increases the machine’s power rating and throug C Sut capability, CS Series cone crushers have the highest capacities for their size in the industry.

CS technology allows you to use either fewer or smaller units to get the highest possible production out of the smallest possible space. Gulin pioneered the CS technology, having developed it in 1989 through extensive pilot and full-size prototype testing. Gulin has been awarded patents for these innovative efforts.

Higher quality

The unique interparticle crushing action of CS Series cone crushers creates a higher value for your product by providing a more consistent gradation and a ior product shape. The ability to operate at a fixed mechanical setting–instead of the head floating on a column of hydraulic oil–creates less setting drift and provides more stability throughout the circuit. The proven benefit of a threaded rotating bowl maintains a consistent setting around the entire circumference of the crushing chamber. Also, the use of a tramp release system with a fixed return point makes sure that the crusher setting is instantaneously maintained even after passing a piece of tramp iron. CS Series cone crushers also enable you to produce a finer product with fewer crushing stages, lowering your capital costs and saving energy

Higher yield

By operating the CS cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of on-spec product. The CS cone crusher creates a higher value product with less waste.

CS series cone crusher Gallery

Parts

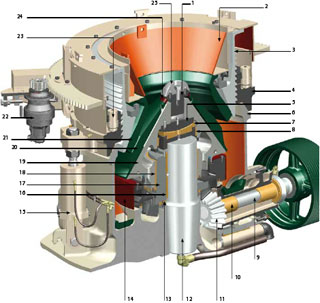

CS cone crusher parts

1-Locking bolt; 2-Feed bowl hopper; 3-Bowl; 4-Adjustment ring; 5-Head bowl; 6-Main frame; 7-Socket liner; 8-Upper head bushing; 9-Countershaft

10-Countershaft bushings; 11-Gear and pinion; 12-Main shaft; 13-Eccentric thrust bearing; 14-Counterweight guard; 15-Tramp Release assembly; 16-Eccentric bushing; 17-Eccentric

18-Lower head bushing; 19-Head; 20-Mantle; 21-Bowl liner; 22-Hydraulic adjustment motor; 23-Clamping cylinders; 24-Torch ring; 25-Cone feed plate

Features

- Multi-crushing chamber: CS Cone Crusher has three models according to its cavity such as fine type, medium cavity type, coarse cavity type etc. Every type of CS Cone Crusher has its own feed opening, discharge setting, output capacity and overall dimension etc. Our clients or users can choose the different crushing chamber which can insure good stone type, high efficiency, size uniformity and long service life of the rolling ace tabular wall according to the working situation.

- High output: Compared with old cone crushers, CS Cone Crusher has long crush arms, long impact distances, high crushing power so that it can crush stone materials more efficiently.

- Low cost of daily operation and maintenance: CS Cone Crusher parts have reasonable selection, structural design which reduced the load of the sliding bearings, gears and rack etc.

- Dry oil seals dust: CS Cone Crusher adopts unique structure to seal dust in order to extend the lubricants’ replacement cycle and the service life of spare parts.

- Flexibility of output discharge setting: CS Cone Crusher has hydraulic adjusting system easy to adjust the discharge.

Specification

| Type | Dia. of cone mm (inch) | Cavity | Feed Opening (mm) | Discharge Setting (mm) | Capacity (t/h) | Counter Shaft (r/min) | Power (kw) | Weight (t) | Overall Dimension (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Closed Side”B” | Opening Side”B” | |||||||||

| CSB75 | 900(3′) | Fine | 83 | 102 | 9-22 | 45-91 | 580 | 75 | 15 | 2821×1880×2164 |

| Coarse | 109 | 175 | 13-38 | 59-163 | ||||||

| CSB110 | 1200(4′) | Fine | 127 | 131 | 9-31 | 63-188 | 485 | 110 | 20 | 2821×1974×2651 |

| Medium | 155 | 156 | 13-38 | 100-200 | ||||||

| Coarse | 178 | 191 | 19-51 | 141-308 | ||||||

| CSB160 | 1295(4 1/4′) | Fine | 109 | 137 | 9-31 | 109-181 | 485 | 160 | 27 | 2800×2342×2668 |

| Medium | 188 | 210 | 13-38 | 132-253 | ||||||

| Coarse | 215 | 241 | 19-51 | 172-349 | ||||||

| CSB240 | 1650(5 1/2′) | Fine | 188 | 209 | 16-38 | 181-327 | 485 | 240 | 55 | 3911×2870×3771 |

| Medium | 213 | 241 | 22-51 | 258-417 | ||||||

| Coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| CSB315 | 2134(7′) | Fine | 253 | 278 | 19-38 | 381-726 | 435 | 315 | 110 | 4613×3251×4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | ||||||

| Coarse | 334 | 369 | 31-64 | 789-1270 | ||||||

| Type | Dia. of cone mm (inch) | Cavity | Feed Opening (mm) | Discharge Setting (mm) | Capacity (t/h) | Counter Shaft (r/min) | Power (kw) | Weight (t) | Overall Dimension (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Closed Side”B” | Opening Side”B” | |||||||||

| CSD75 | 914(3′) | Fine | 13 | 41 | 3-13 | 27-90 | 580 | 75 | 15 | 2821×1880×2410 |

| Coarse | 33 | 60 | 3-16 | 27-100 | ||||||

| CSD110 | 1218(4′) | Fine | 29 | 57 | 5-16 | 50-132 | 485 | 110 | 20 | 2560×1942×2928 |

| Medium | 44 | 73 | 10-16 | 90-145 | ||||||

| Coarse | 56 | 89 | 13-19 | 141-181 | ||||||

| CSD160 | 1295(4 1/4′) | Fine | 29 | 64 | 3-16 | 36-163 | 485 | 160 | 27 | 2800×2342×2668 |

| Medium | 54 | 89 | 6-16 | 82-163 | ||||||

| Coarse | 70 | 105 | 10-25 | 109-227 | ||||||

| CSD240 | 1676 (5 1/2′) | Fine | 35 | 70 | 5-13 | 90-209 | 485 | 240 | 55 | 3917×2870×3771 |

| Medium | 54 | 89 | 6-19 | 136-281 | ||||||

| Coarse | 98 | 133 | 10-25 | 190-336 | ||||||

| CSD315 | 2134(7′) | Fine | 51 | 105 | 5-16 | 190-408 | 435 | 315 | 110 | 4130×3251×4454 |

| Medium | 95 | 133 | 10-19 | 354-508 | ||||||

| Coarse | 127 | 178 | 13-25 | 454-599 | ||||||