Portable limestone crushing plant is the major crushing equipment in limestone quarry. Limestone production flow mainly include: limestone crushing and transportation, raw material pre-homogenizing, raw material preparation, raw material homogenizing, warm-up decomposition, sintering clinker stone crusher, limestone grinding and limestone packaging.

Crushed Limestone Application

- Cement is a mixture of limestone, clay and others processed by high temperature calcinations.

- Glass is from the limestone, quartz sand, soda ash and other mixture, and obtained by high temperature melting, iron with limestone used as flux to remove gangue, in steelmaking use lime to form slag materials to remove sulfur, phosphorus and other harmful impurities.

- Calcium carbide (main ingredient is CaC2) is from the lime and coke reacted in the furnace.

- Soda ash is produced by limestone, salt, ammonia and other raw materials through multi-step reaction (Solvay method).

- Soda lime and soda ash reaction (Caustic method) make caustic soda. Using pure lime and chlorine reaction to bleach. The chemical processing of limestone make the calcium chloride, calcium nitrate, calcium sulfite etc.

- Lime is used to soften water and can remove temporary hardness of the water.

- Burning limestone processed into a more pure calcium carbonate powder, is used as filler of rubber, plastic, paper, toothpaste, cosmetics, etc. The soda lime made by caustic soda with lime for carbon dioxide absorbent.

- Quicklime is used as a dryer and disinfectant. In agriculture, lime sulfur mixture is mixed with lime, as well as Bordeaux mixture and other pesticides.

- The application of hydrated lime to the soil can neutralize the soil acidity and improve soil structure, supply plant-available calcium. Brush the tree trund with lime liquid can protect trees.

Portable Limestone crushing plant reference design factors:

- The design of a limestone crushing plant is usually decided by several factors:

- PE Series high performance jaw crushers

- Incorporated the feeder and vibrating screen into the crusher

- Everything on board: crusher, feeders, screens, belts and power installations

- Quick road transportation thanks to king pin arrangement

- Installation support legs on the track, quick to set-up

- Electric motor and control cabinet are on the same truck

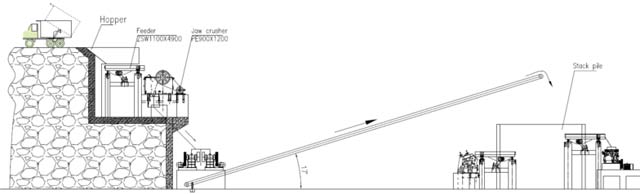

Portable Limestone quarry process:

For the limestone crushing plant: 40-60tph, 100-120tph, 150-180tph, 200-250tph, 300-350tph, 350-400tph, 500-600tph, 600-800tph and 800-1000tph, we here recommend three proposals:

Proposal 1: vibrating feeder + primary Jaw crusher + impact crusher + Vibrating screen + belt conveying system + control system

Proposal 2: vibrating feeder + primary Jaw crusher + fineness Jaw crusher + impact crusher (optional) + vibrating screen + belt conveying system + control system

Proposal 3: vibrating feeder +primary Jaw crusher + cone crusher + impact crusher (optional) + vibrating screen +belt conveying system + control system

In the above proposals, the main difference is the secondary crusher: using impact crusher (hammer crushing principle), or using fineness Jaw crusher (plate pressing principle), or Compound cone crusher (plate pressing principle).