Gulin™ is a leading manufacturer & supplier of gold refining machine in China, and we supply the best type of crushers for gold/copper mines, such as jaw crushers, cone crusher and impact crusher, mobile crushers, our centrifugal gold concentrator is popular in Philippines, south Africa, India, USA, Pakistan, UK, UAE and other countries.

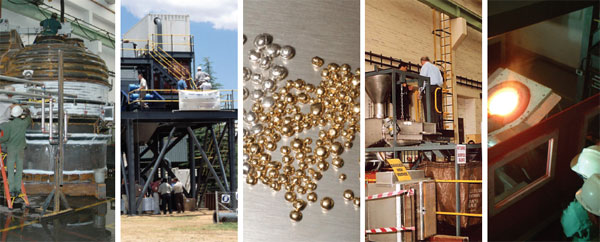

Gulin gold refinery

The Gulin™ refining technology is a unique all hydrometallurgical route, based on solvent extraction, for refining gold to a purity of “five nines” (99.999 per cent). Compared with conventional smelting and electro refining technology, the Gulin process offers:

- Significantly reduced lock-up times of the gold;

- Easier operation and control;

- The ability to directly produce a high purity product onsite.

It is particularly attractive for feed materials containing significant quantities of base metals.

The process comprises oxidative leaching of the feed material in a chloride medium, followed by selective solvent extraction of the gold to reject impurities. The loaded organic phase is then stripped to produce a purified, concentrated gold solution, from which high purity gold powder is precipitated by reduction. The leach and reduction are operated batch wise, while the solvent extraction is a continuous operation.

The gold content of the feed can range from about 20 per cent to 99 per cent. Suitable feeds include silver refining anode slimes, gold electro winning cathode sludge, zinc precipitation filtrates, dorè bullion and jewellery scraps. Materials with variable gold contents can be handled.

Centrifugal gold concentrator

The centrifugal gold concentrator is suitable for fine feed applications requiring low mass recoveries. Its bowl uses no fluidizing water; concentrates are simply retained against the wall of the bowl. The centrifugal gold concentrator may offer metallurgical benefits such as improved recovery of fines and possibly concentrate grade in the fine particle size ranges. In cases where scavenging very fine gold bearing particles is more important than the grade of concentrate produced, the centrifugal gold concentrator may be of considerable metallurgical value if the optimum operating conditions can be determined.