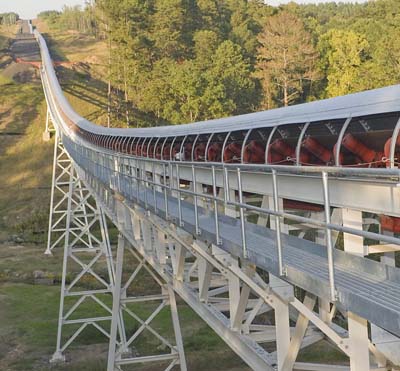

Continental belt conveyor

Continental Conveyor’s product line includes belt conveyors, screw conveyors, conveyor pulleys, conveyor idlers, bucket elevators, vibrating feeders and conveyors, bin activators, en masse chain conveyors, screw reclaimers, stoker reclaimers, stackers, apron feeders and weighfeeders. Continental also designs and develops complete engineered systems.

Continental Conveyor Products

Belt Conveyors

Continental belt conveyors need a single sentence introduction to place here.

Bucket Elevators

Ruggedly built for a long service life in a wide range of applications.

Screw Conveyors

The basic principle of the screw conveyor remains unchanged today

from when Archimedes first used an internal type helix to remove water

from the hold of a ship.

Weighfeeders

Continental weighfeeders are self-contained belt feeders with a controlled drive system, belt scale, speed sensor and integrator. They are designed to operate in either the shearing or wild flow modes of weighfeeding.

Apron Feeders

Our Apron Feeders are designed for feeding and conveying heavy, lumpy or abrasive materials under severe conditions.

Conveyor Components

Belt Conveyor Idlers

For continuous operation, high capacities and heavy abrasive materials.

Belt Conveyor Pulleys

The pulleys described herein are those meeting standard specifications. They are by no means a limit to Continental’s abilities in the engineered class applications as custom pulleys are designed and fabricated to meet customers individual requirements whenever necessary.

Conveyor Covers

Conveyor covers are used to protect transported material and conveyor belting, idlers and structure. They effectively improve personnel safety, reduce loss of material to wind and stop grime and rain from damaging the idlers and belt.

Underground Conveyors

As every miner knows, it’s a different world underground, and Continental knows that requires solving some very specialized problems for difficult and harsh conditions.

Overland Conveyors

Continental designed overland systems are used extensively in mining and construction industries throughout the world. Continental’s mining type structure has been the ideal selection for many of these applications.

Conveyor Components

Continental is the world leader in conveyors and conveyor technology. Continental belt conveyor components move more material, in more places, than any other brand of belt conveyor components.

High Angle Conveyor

Since the early 1980’s the Continental® HAC® (High Angle Conveyor) has proven itself to be a versatile and money saving method for elevating or lowering materials continuously from one level to another at extremely steep angles.

Continental belt conveyor Supplier

Continental Screw Conveyor has built, supplied and manufactured quality bulk material handling equipment since 1926 starting with the original Continental Gin Company. As a primary supplier of custom-designed screw conveyors, bucket elevators and drag conveyors, the next logical step in the material handling industry is belt conveyors. Gulin will offer these belt conveyors as stand-alone equipment or in combination with the other equipment we manufacture. Now you will be able to look at one company with the responsibility-to provide all of your mechanical bulk material handling equipment requirements. This could be as individual items of equipment or designed together as an engineered system. That single source company is Continental Screw Conveyor.

| Belt Width (mm) | Belt Length (m) / Power (Kw) | Belt Speed (m/S) | Capacity (t/h) | ||

|---|---|---|---|---|---|

| 400 | ≤12/1.5 | 12~20/2.2 | 20~25/3 | 0.8~2.0 | 40~80 |

| 500 | ≤12/3 | 12~30/4 | 20~30/5.5 | 0.8~2.0 | 78~191 |

| 650 | ≤12/4 | 12~20/5.5 | 20~30/7.5 | 0.8~2.0 | 131~323 |

| 800 | ≤10/4 | 10~15/5.5 | 15~25/7.5 | 1.0~2.0 | 278~546 |

| 1000 | ≤10/5.5 | 10~20/7.5 | 20~25/11 | 1.0~2.0 | 435~853 |

| 1200 | ≤10/7.5 | 10~20/11 | 20~25/15 | 1.0~2.0 | 655~1284 |