Gulin® is a professional aluminum ore beneficiation plant manufacturer in China, we supply aluminum crusher and grinding mills for aluminum processing, dressing flow process, if you are ready to buy a cost-effective machine, then no doubt we are your best choice!

Aluminum Ore Beneficiation Plant

Aluminum ore beneficiation plant

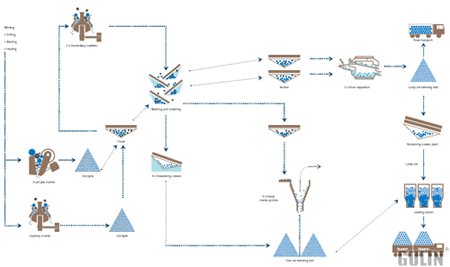

Our company specializes around the design, specific engineering, provide, erection and commissioning of Aluminum beneficiation plants. we supply Kinds of beneficiation machine include crusher, jigging, shaking table, spiral separator, flotation machine, ball mill, belt conveyor, feeder, vibrating screens.

Main beneficiation(dressing) machine

Drier is required in metallurgy, exploration, substance plant, for drying steel concentrates, trail ore and feed. It’s also standard drying gear in concrete plant. This equipment includes a great usefulness for substance and will dry various components.

Flotation machine is the newest design and style to apply the circular tank strategy and includes the advantages of circular cells using the unique attributes of the Minerals device to produce the ideal conditions to increase floatation functioning for many roughing, cleaning and scavenging responsibilities.

Magnetic separator is seen as a turbulent magnetic area and great separation issue, advanced construction, light-weight, dependable operation and hassle-free maintenance. It’s very suited to the zones which are lacking water to ensure that water resource could be saved and ore dressing coasts can be lowered.

Aluminum ore processing processing

Aluminum dressing is usually a approach in which beneficial constituents of the ore are concentrated through a actual separation technique. While some of the original methods of extractive metallurgy, the primary goal is always to make the ore ahead of downstream refinement processes. The most typical mineral beneficiation techniques consist of: sample preparation, comminution, measurement category, and concentration.

Key Aluminum beneficiation process

The key Aluminum beneficiation process contains: gravity separation, floatation, powerful magnetic beneficiation or mix numerous beneficiation process and the other process is magnetization roasting after which weak magnetic separation. The initial Aluminum beneficiation mainly used the gravity separation process, and also the main equipments are: jigger, centrifugal separator, spiral chute, spiral washer, shaking table and so on. Due to the fact another beneficiation’s manufacturing capacity is small-scale, the level after processing was lower, recovery relation is low then was got rid of as time passes. Afterwards since the Aluminum beneficiation constructing, the floatation process as intense magnetization process. It mostly use oxidized paraffinum salt sodium being the collector for floatation and electro-magnetic quality magnetic separator as Aluminum beneficiation equipment for strong magnetic separator. However the others beneficiation technology focuses on counseled me not adequate enough. Those recent years, the beneficiation process of Aluminum has evolved perfectly. Specifically utilize the intense magnetic separation that is can increase the rate of iron ore concentrate well, and the recovery of Iron ore concentrate is fulfilling.